|

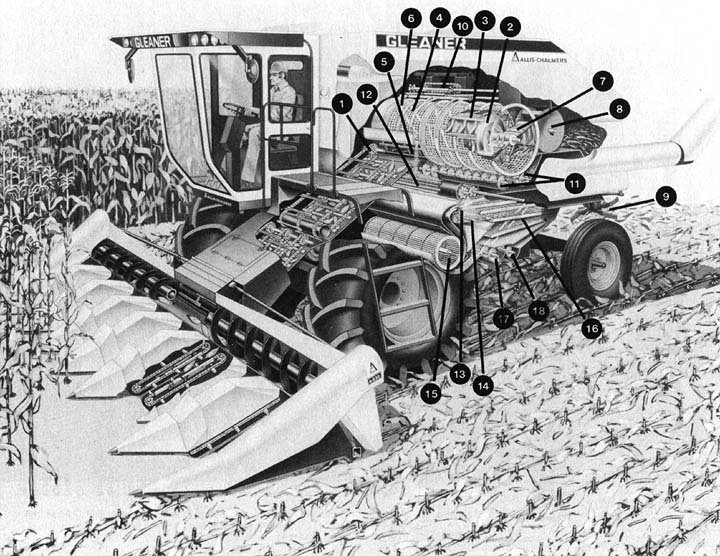

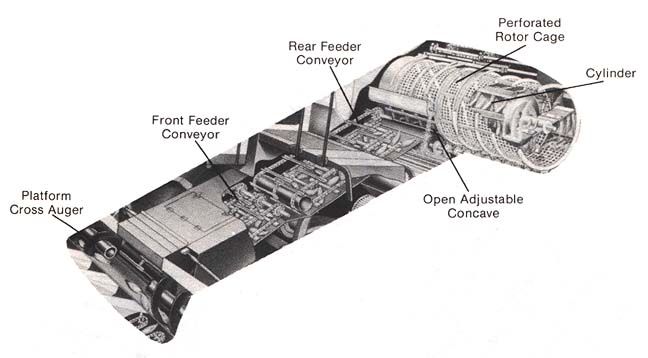

The transverse

flow rotor combine feeds the material directly into the rotor

(1) from the feeding unit. The material then changes direction

in the rotor threshing cage and spirals around the cage toward

the exit at the left end. The rotor (cylinder) (2) is made up

of eight equally spaced rasp bars (3) and mounted inside a perforated

metal cylindrical cage (4). The material is fed perpendicularly

to the cylinder. The first portion of the cage which the crop

is fed into is an adjustable open concave section (5) where most

of the threshing action takes place. Helical bars (6) on the

inside of the cage and the angled rasp bars (3) on the cylinder

then move the material from right to left in a spiral path around

the cylinder. Grain is separated from the material by centrifugal

force. Since the cage is completely perforated, separation takes

place in all parts of the cage. At the left end of the cage,

paddles (7) on the cylinder shaft direct the material to a beater

(8) which discharges the material to a straw spreader (9). To

prevent buildup of chaff on top of the cage, an oscillating cage

sweep (10) is provided. For cleaning, the material passing through

the perforated cage falls into the distribution auger (11) which

deliver it to a pair of accelerator rolls (12). The rolls have

overlapping flutes and turn in opposite directions to accelerate

the material through a band of high velocity air (13), where

initial cleaning takes place, onto the shoe grain pan (14). In

the second stage of cleaning, the fan (15) directs air to the

shaker type cleaning shoe (16) Clean grain falls into the clean

grain auger (17) and is delivered to the clean grain tank. The

tailings pass over the end of the cleaning shoe and fall into

the tailings auger (18) where they are returned to the accelerator

rolls for recleaning. This particular combine has a corn head

on it, but other than that, the functions are identical for harvesting

other crops. |

|

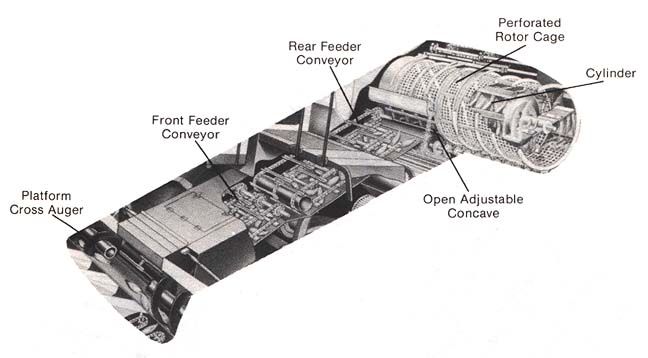

Here

is an enlarged view of the initial feeding section and the cylinder

assembly. |

|

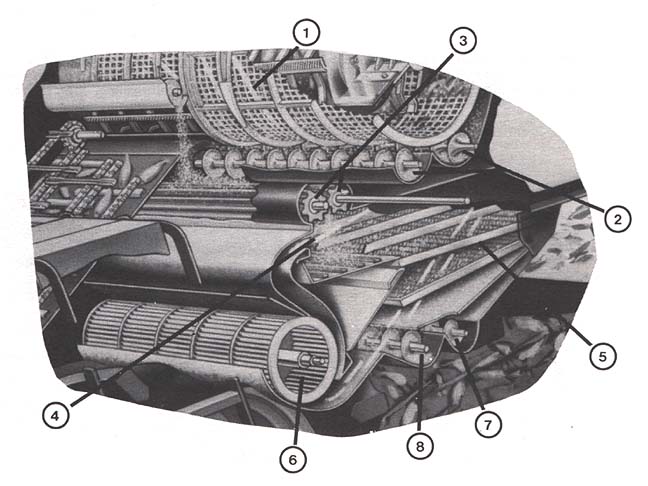

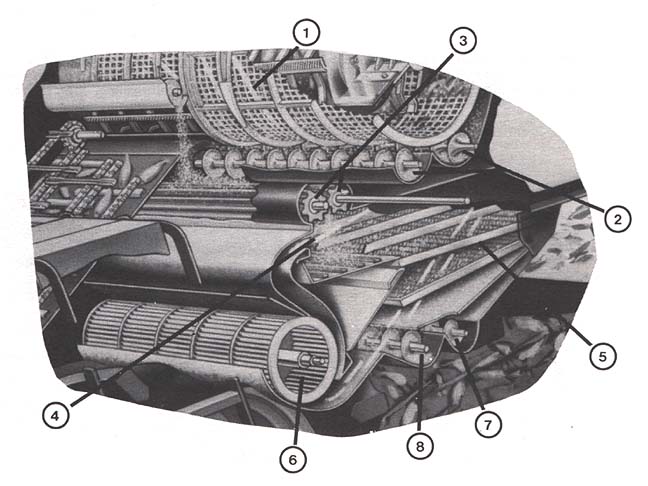

The grain

and chaff fall from the cylinder cage (1) into the distribution

augers (2). The material is then delivered to the accelerator

rolls (3). The accelerator rolls speed movement of the grain

and chaff to over four times the natural rate of falling, past

a blast of air for pre-cleaning (4). Much of the chaff is blown

out the rear of the machine; the remainder of the material falls

onto the cleaning shoe area (5). The air for the two stages of

cleaning is provided by the fan (6). Unthreshed heads fall into

the tailings auger (7) where they are returned to the accelerator

rolls (3). The clean grain then falls into the clean grain auger

(8) and is delivered to the clean grain tank. |

|